Inert Atmosphere Furnace

Features

- Maximum operating temperature range up to 1800°C.

- Compact design for minimum space requirement.

- Rugged and durable Construction.

- Outer casing is made up thick mild steel with duly powder coated or thick buffed stainless steel, gives long service life with extremely resistant.

- Multilayer insulation with vacuum formed ceramic fibre or refractory bricks with low thermal mass.

- High Purity Alumina/Quartz/Metal tube with two fibre plugs included.

- Furnace design with powerful heating elements i.e. FeCrAl, SiC and MoSi2 in all sides of the work tube providing fast heating rate.

- Vacuum provide by turbo molecular pump/Rotary vane pump with pirani/penning gauges and related fittings.

- Gas connections with Digital Mass Flow Controller or Rotameters.

- Fast heat up and cool down rates.

- Temperature uniformity +/- 5°C.

- Temperature control with PID controllers.

- Power control with thyristor units for very precise temperature Control, wear-free and noiseless.

- High mechanical durability, short heating cycle and low power consumption.

Optional

- Touchscreen temperature controller

- Over Temperature Limiter.

- Gas control system with flow controller.

- Vacuum pump with fittings

- Gas and Vacuum Compatible Flanges, Water cooled flanges with chiller.

- Door flanges with hinges.

- Gas mixing system.

- Vacuum pump with fittings.

- Port for additional thermocouple on the flange.

- Process observation window on flange.

- Buzzer, Digital timer, Emergency shut down.

- Data Recorder.

- RS232/RS485/USB interface.

- Calibration of temperature measurement systems.

- Table/Stand for supporting the systems.

- Data Acquisition System (DAS) through software.

- UPS Systems.

- Customization as per user requirement.

- Caster wheels with brakes.

- Furnace furniture.

Applications

Inert Atmosphere Furnaces are specially design for heat treatment applications such as sintering and annealing process with inert atmosphere. Inert atmospheres are made of purified argon and nitrogen gases, due to their high natural abundance. Inert atmospheres may include helium, nitrogen, argon, hydrogen, and endothermic mixtures Inert atmosphere furnaces are designed for R&D labs, Automotive Industries, Aerospace Industries, Petrochemical Industries, Educational Institutions, Medicine and Industry, Chemical Industries, Biomedical Industry, Pharma Industry, Thermal Process Technology, Advanced Materials for following applications- Chemical analysis, Physical decomposition, sublimation, Purification, Coating, Drying, Hardening or Ageing of samples, Brazing, Calcination, Degassing, Sintering, Tempering, Testing of fuel cells, Catalyst research, Inorganic and Organic purification, Coating etc.

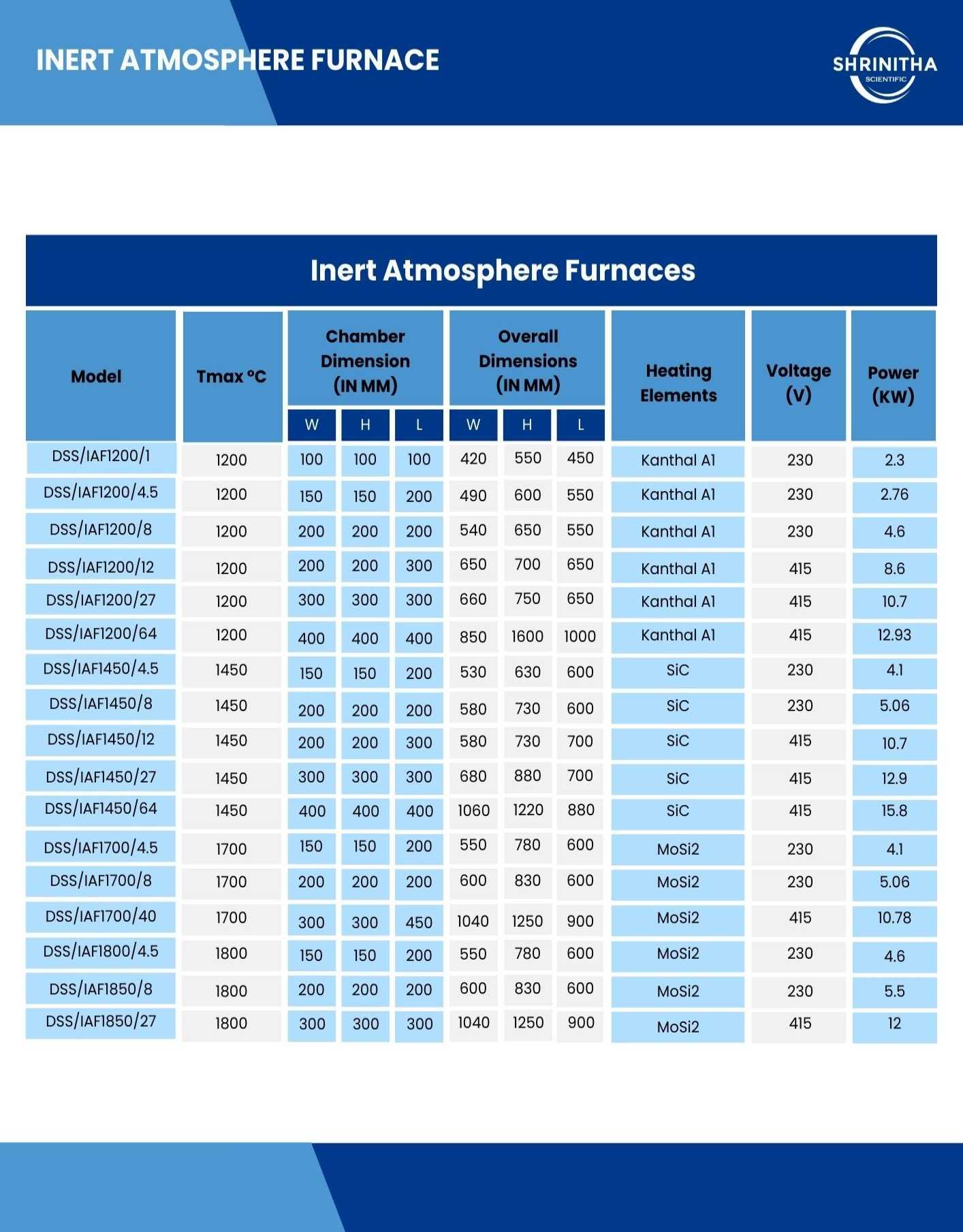

Specification Sheet

Products Gallery

Our Expertise’s

Precision Engineering

Innovative Solutions

Quality Assurance

Customer

Focus