Top Loading Furnace

Features

- Maximum operating temperature range up to 1450°C.

- Available in various capacity, from 1litres to 1000 liters.

- As the name states itself, top loading furnaces are made vertical heating chambers; where material or crucible is put from top. Door is fitted on top, which is lift up to open and put down to close. Usually such furnaces are used to put crucibles; therefore, these furnaces are also called crucible furnace.

- These Top loading chamber furnaces are particularly suited for applications involving tall crucibles and heavy components.

- Top cover allows better heat shielding and more uniform heating area.

- Top opening provides good ventilation inside the chamber and allow the furnace to fast cooling.

- Ideal for heavy components and provides safety in loading/Unloading.

- Sturdy, locking castors for easy movement of the system.

- Compact design for minimum space requirement.

- Rugged and durable Construction.

- Outer casing is made up thick mild steel with duly powder coated or thick buffed stainless steel, gives long service life with extremely resistant.

- Multilayer insulation with vacuum formed ceramic fibre or refractory bricks with low thermal mass.

- Furnace design with powerful heating elements i.e. FeCrAl, and SiC in all sides of the work tube providing fast heating rate. Heating elements in all four walls minimize the risk of damage from, spills and ensure good temperature uniformity.

- Fast heat up and cool down rates.

- Temperature control with PID controllers.

- Power control with solid state relays or Thyristor units for very precise temperature Control, wear-free and noiseless.

- High mechanical durability, short heating cycle and low power consumption.

Optional

- Over temperature/Over current Limiter.

- Touchscreen temperature controller

- Process observation window.

- Chimney for forced air extraction.

- Buzzer, Digital timer, Emergency shut down.

- Data Recorder.

- RS232/RS485/USB interface.

- Calibration of temperature measurement systems.

- Table/Stand for supporting the systems.

- Data Acquisition System (DAS) through software.

- UPS Systems.

- Customization as per user requirement.

- Caster wheels with brakes.

- Door safety switch.

- Furnace furniture.

Applications

Top Loading Furnaces are designed for R&D labs, Educational institutions, Medicine and Industry, Ceramics Industry, Biomedical Industry, Glass industry Pharma Industry, Thermal Process Technology, Advanced Materials for following applications:

Drying, Hardening, Annealing, Brazing, Degassing, Sintering, Tempering, , Testing of fuel cells, Inorganic and Organic purification, Heat treatment, Stress releaving, Component Testing, Preliminary Heating, Loosening, Normalising, Melting etc.

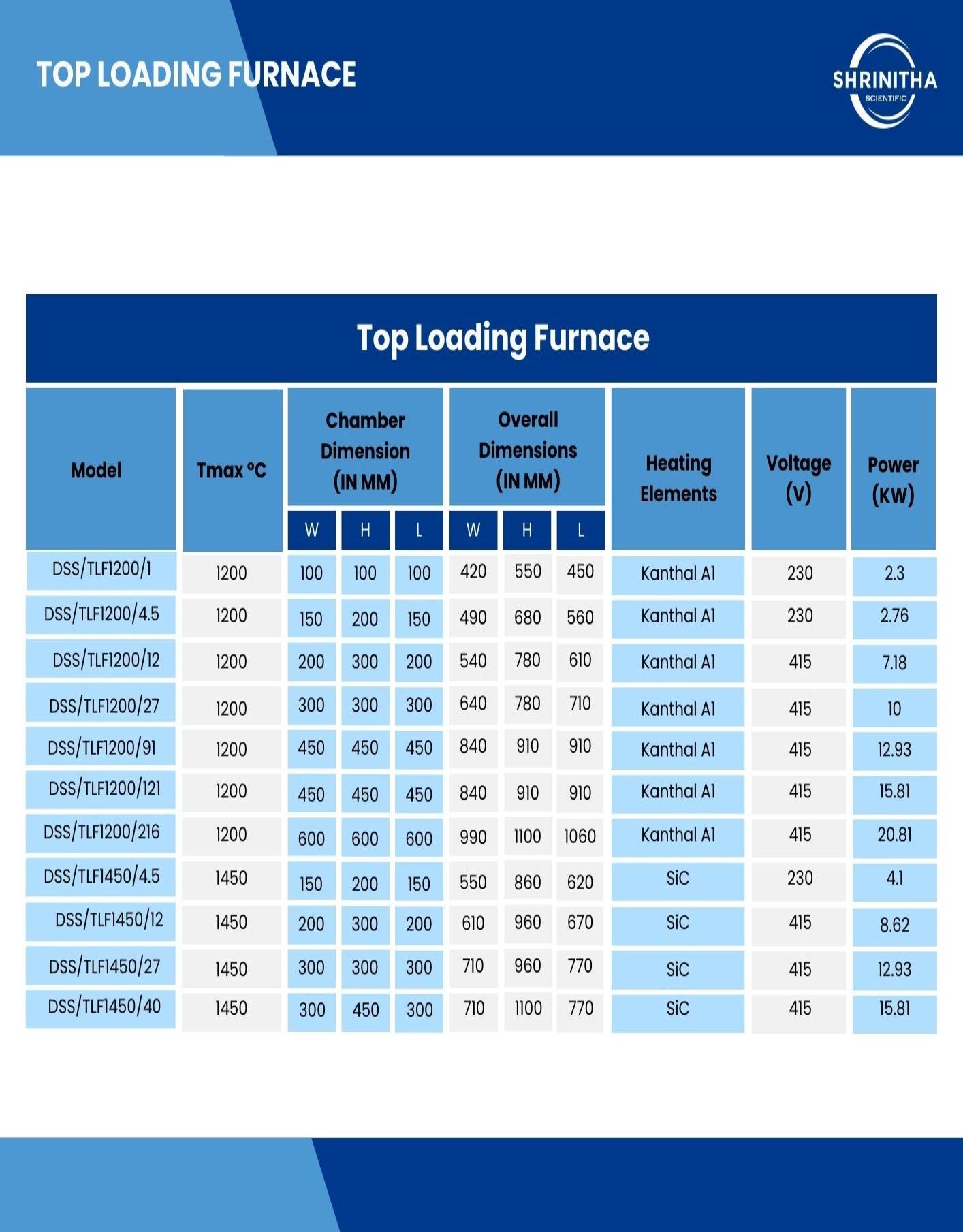

Specification Sheet

Products Gallery

Our Expertise’s

Precision Engineering

Innovative Solutions

Quality Assurance

Customer

Focus